The use of Barcode and Biometric Technology in the Automotive Industry

Barcode scanners are powerful tools used to quickly and accurately retrieve information contained in barcodes, making it a valuable asset in a variety of industries.

One area where barcode scanners have proven particularly useful is in job costing. Job costing is the process of tracking the cost of individual jobs or projects, so that a business can determine the profitability of each undertaking. This is important because it allows companies to identify areas where they may be losing money, and to make adjustments to their processes or pricing accordingly.

Barcode scanners can help with job costing by simplifying the process of tracking the time and materials used for each job. For example, a manufacturing company may use barcode scanners to track the amount of raw materials used in the production of a specific product. By scanning the barcode associated with each batch of materials, the company can quickly and accurately record the amount used for each job, allowing them to calculate the exact cost of production.

Similarly, barcode scanners can be used to track the time spent on each job by employees. This can be particularly useful for service-based businesses, such as consulting firms or repair shops, where the cost of labour is a significant factor in the overall cost of each job. By scanning a barcode associated with each job, employees can quickly and easily log the amount of time spent on the project, allowing the business to accurately track the cost of labour for each job.

Overall, barcode scanners are powerful tools that can help businesses of all types and sizes with job costing. By simplifying the process of tracking time, materials, and inventory levels, these devices can help businesses accurately calculate the cost of each job, identify areas where costs can be reduced, and ultimately increase profitability. As such, barcode scanners are an investment that businesses should seriously consider if they are looking to improve their job costing processes.

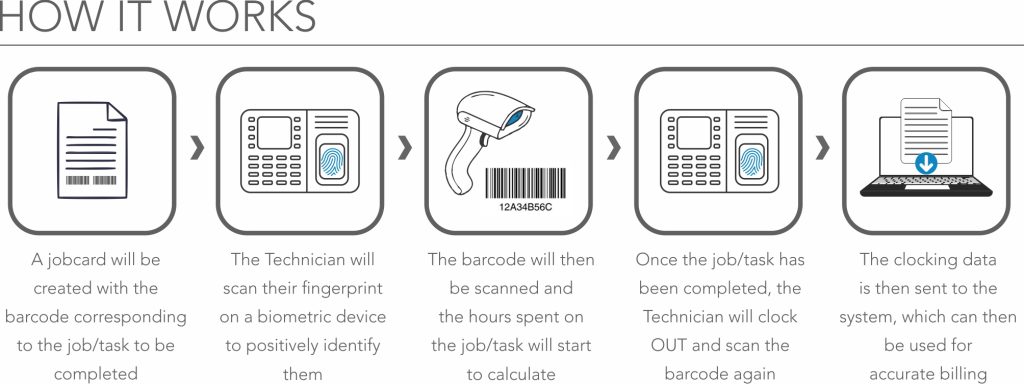

This has led ERSBio to develop a system where barcode scanners are used in conjunction with biometric fingerprint devices. It was specifically designed to accurately track hours on tasks or jobs. In its simplest form, an employee will clock in on a biometric device using their fingerprint, thereafter they will scan a barcode indicating a specific job, such as “oil change” or “rotating tyres”. Once the job is done, they will clock out on the biometric device and scan the barcode again.

The system will then automatically calculate the hours spent on a job. It allows for multiple labour lines on a single job, and will also be able to separate each technician’s individual work times for when multiple technicians has worked on one job.

Each time a technician clocks IN and OUT on one of these jobs/tasks, the total hours will automatically add up, resulting in accurate billing, and also ensuring that the technicians are being truly productive.

ERSBio has seamlessly integrated with the Evolve Dealer Management System (DMS). Evolve is used by about 50% of the dealers in South Africa to manage the dealership, from Vehicle and part sales to Servicing of vehicles. Once a technician has clocked out, and the job is finished, the clocking data is sent to Evolve, where the clocked times are saved for audit purposes and the time worked is calculated per labour line on the job.

Additional add-ons on the system also include:

- Time & Attendance

- Access Control

- Visitor Management

- Breathalyzers

For more info on the ERSBio’s Automated Time & Attendance terminals, click here.

For more on ERSBio’s Time & Attendance Software, click here.

Contact us: sa***@*******co.za l 010 593 0593